Master Plus

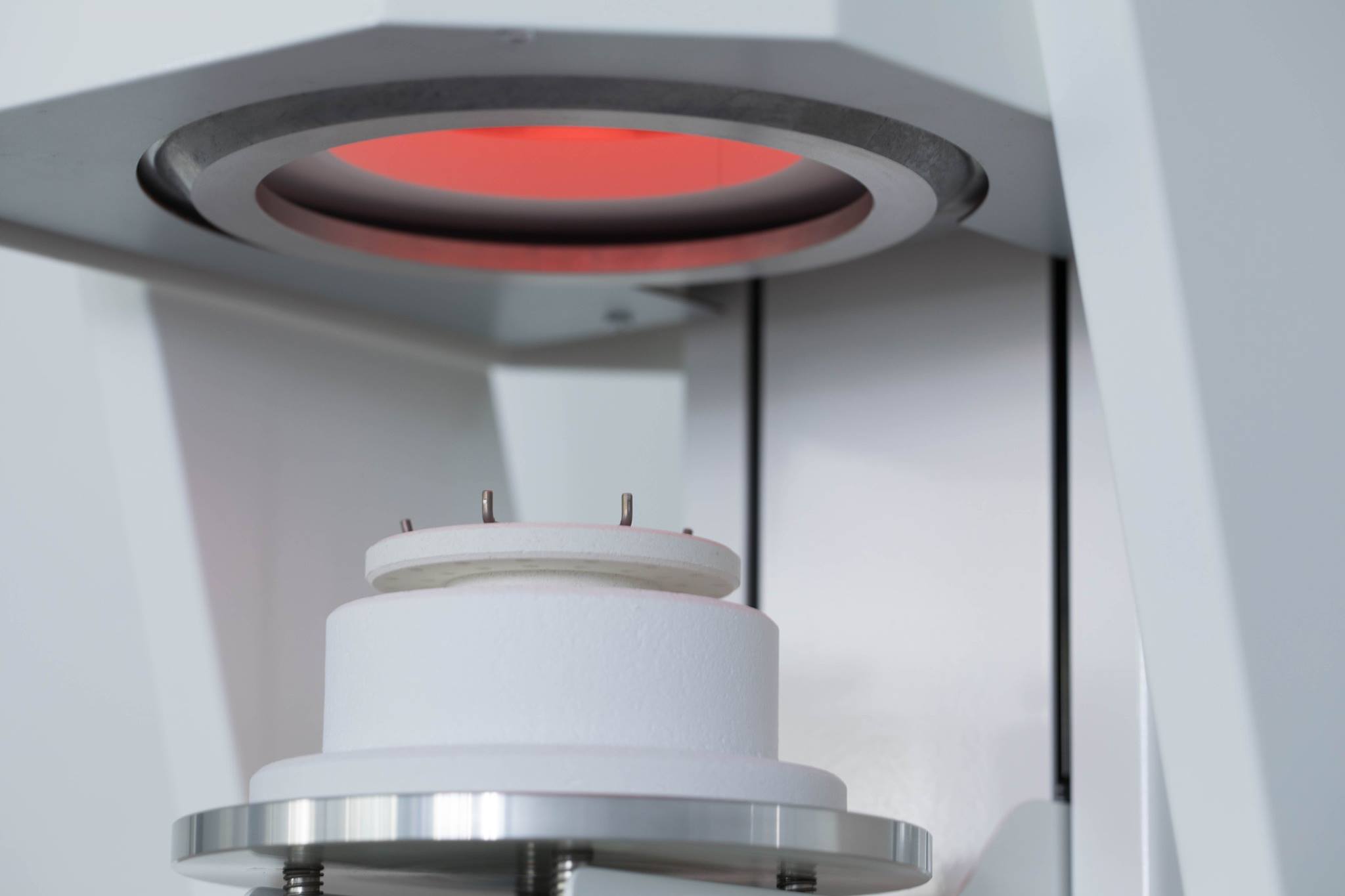

This is not only a Porcelain oven but is also used for zirconia material’s Staining and Glazing.

The Master Plus programming system is for all materials acceptable. Fastest finishing zirconia works will be only 100min with Zircom Speed and Master Plus.

Master Plus

Porcelain Furnace

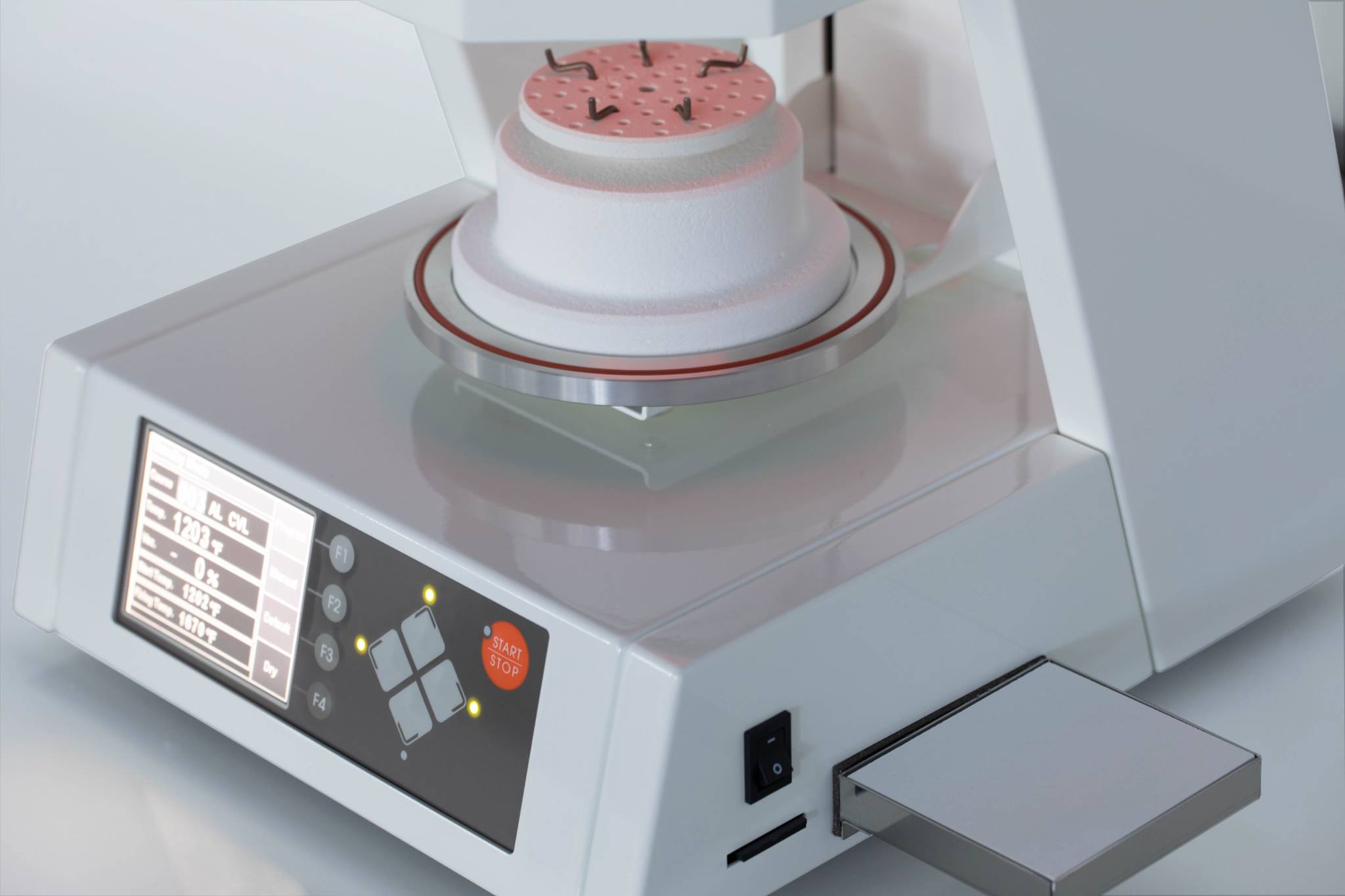

This newly development Master Plus is standardized, compact, and easy to use.

This programmable porcelain furnace allows the technician to program up to 500 courses.

160 courses have been pre-programmed and adjustable

at the technician’s preference.

Product Information

- Up to 30 courses can be used as a 2-step firing process.

- It’s manual mode help technicians to change the setting during the firing process.

- The Master Plus comes with a vacuum pump and a 2-year limited warranty (the muffler has a 6-month warranty).

Specifications

Power Requirement:

AC 100V. 50/60Hz

Dimension:

10 (w) x 17 (h) x 12 (d) inches

Display:

LCD Color Display

Firing Platform:

Ø93mm (3.66 inches)

Weight:

35 lbs (15kg)

Max Temperature:

1,200°C (2,192°F)

Programs:

500 (160 pre-programmed)

SD Card Slot:

Software Update

Program Back Up

Warranty:

2 Year Limited Warranty (Muffle 6 month warranty)