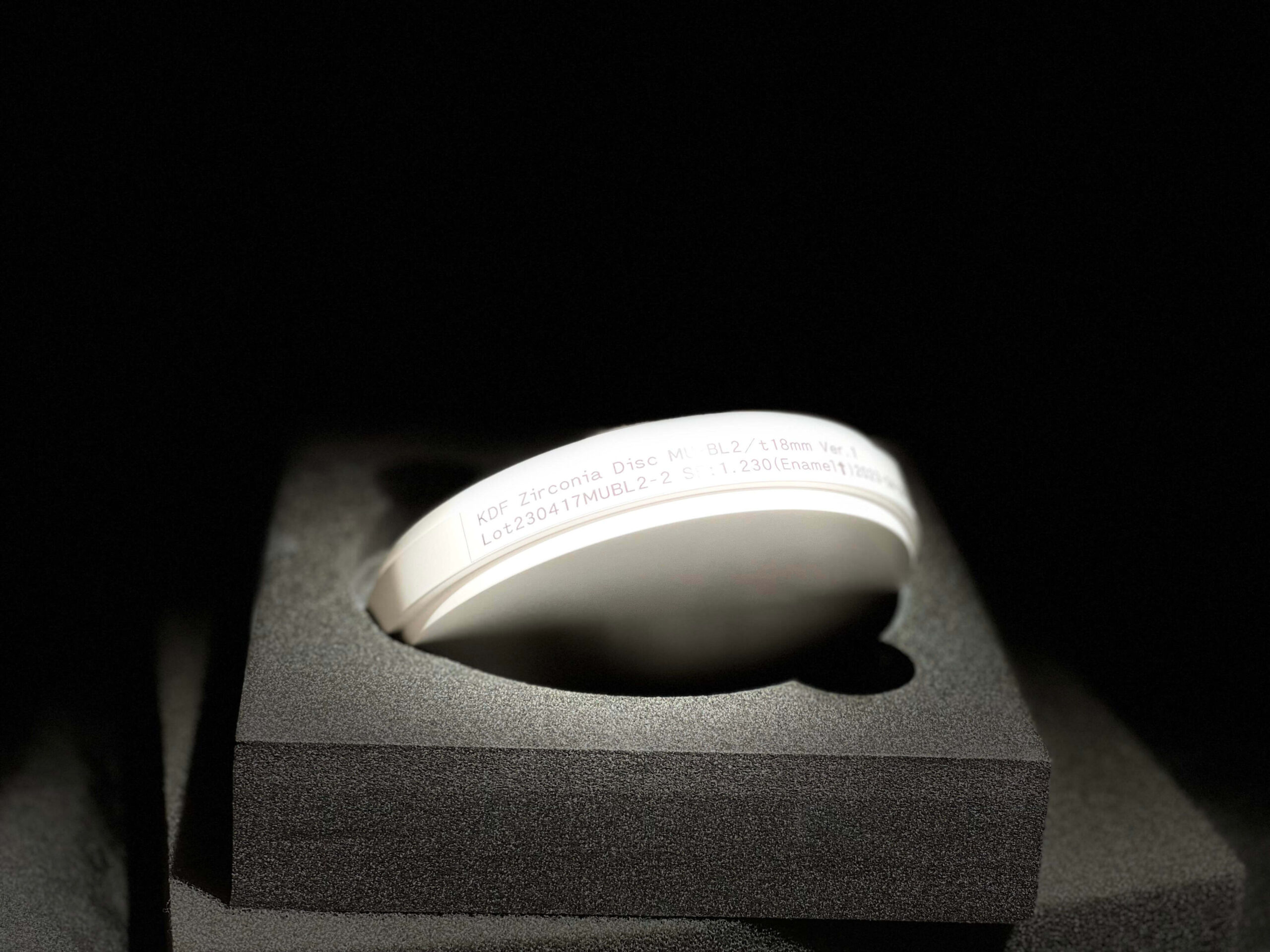

KDF Zirconia Disc

The purpose of “KDF Zirconia Disc” is to fabricate dental ceramic prosthetics such as inlays, anlays, veneers, artificial teeth, crowns, and bridges.

The prosthetics are designed by a dental technician or dental specialist, and machined into prosthetic shapes by CAD/CAM machines. This device is applied to the anterior or molar region.

KDF Zirconia Disc

“KDF Zirconia Disc” are manufactured by mixing raw materials,

pressing them into disc shapes, and then semi-sintering them in a sintering furnace.

The devices are milled prosthetic shapes using CAD/CAM

machines and then fully sintered (secondary sintering), and the

zirconia acquires its final physical properties by forming a crystalline structure.

The fabricated prosthesis is chemically bonded to the defect,

abutment tooth or conducted core on the remaining tooth using resin cement.

KDF Zirconia Disc Firing Schedule for KDF Zircom Machines

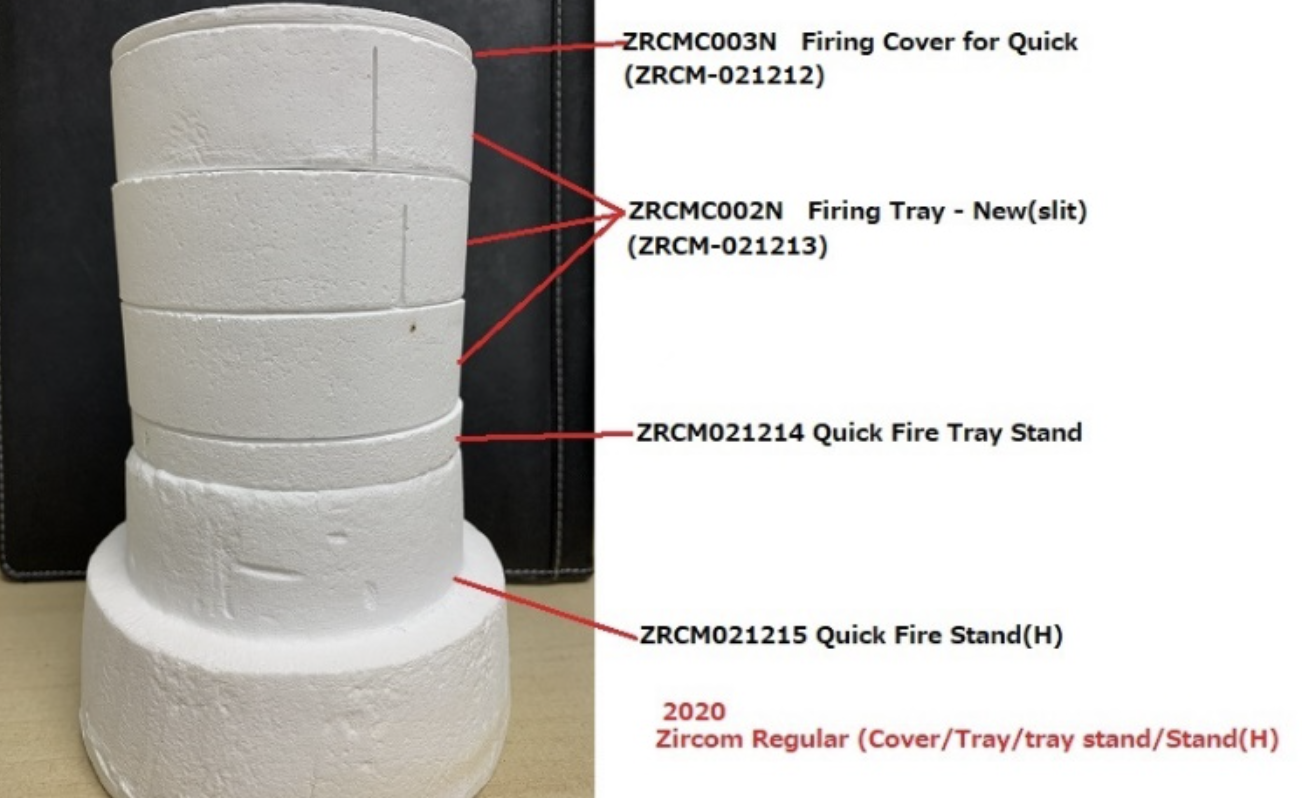

Normal Firing Schedule

(Zircom Standard/ Zircom Plus/ Ceramic Tray use of Zircom Speed)

Temp (℃) | Time (h:m) | |

Step 1 | 1500 | 3:05 |

Step 2 | 1500 | 2:00 |

Step 3 | 400* | 2:18 |

Total 7:23 |

Note: *Original Schedule natural cooling to 20℃ But Zircom machine has programmed open the table reached under 400℃ for cooloing.

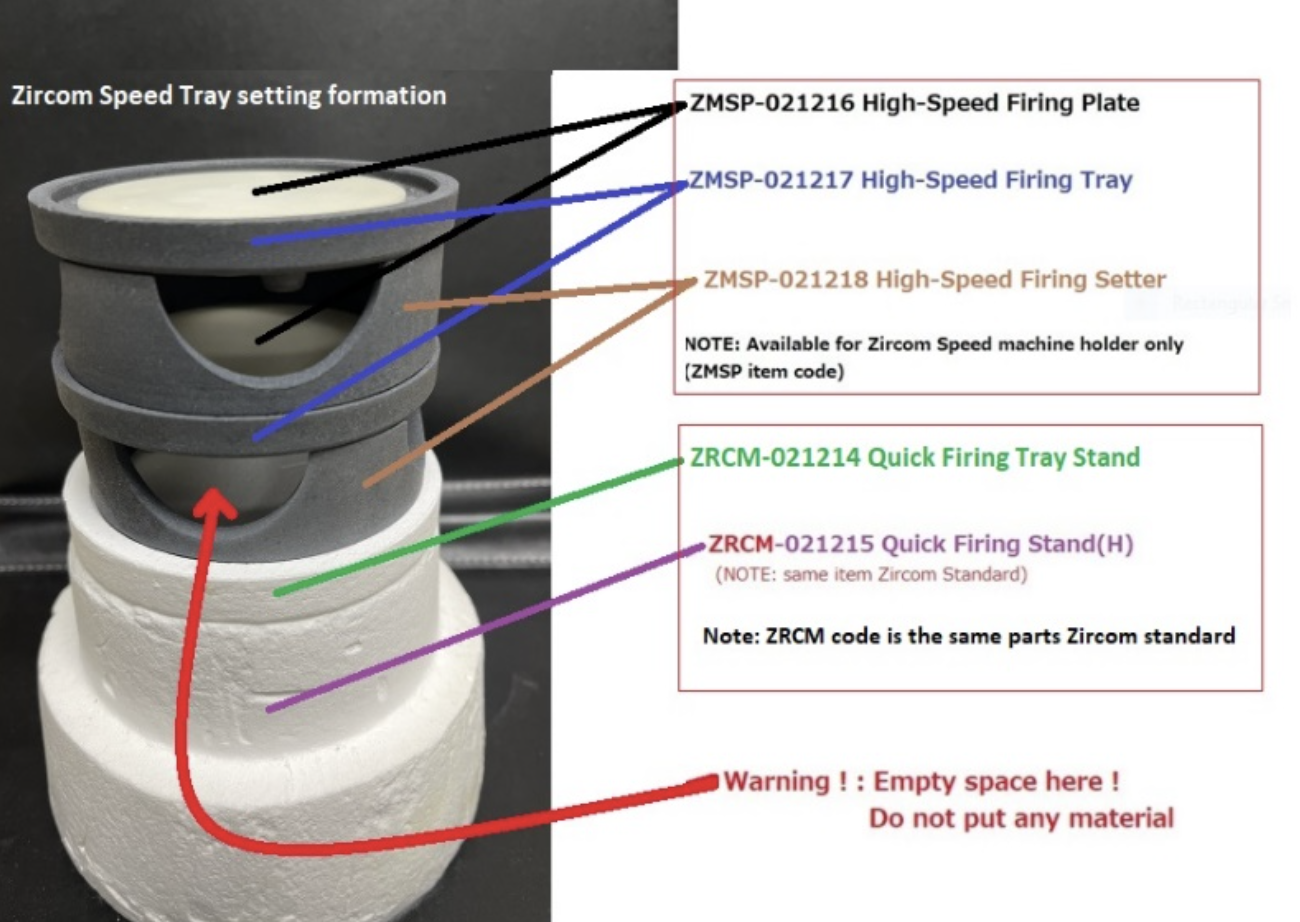

High Speed Firing Schedule

(Only Zircom Speed machine use with SiC Black Trays)

Temp (℃) | Time (h:m) | Table Level | |

Step 1 | 1000 | 0:12 | |

Step 2 | 1500 | 0:18 | |

Step 3 | 1500 | 0:30 | |

Step 4 | 1400 | 0:03 | |

Step 5 | 1200 | 0:05 | |

Step 6 | 800 | 0:12 | 5* |

Total 1:20 |

Note: * for quick cooling