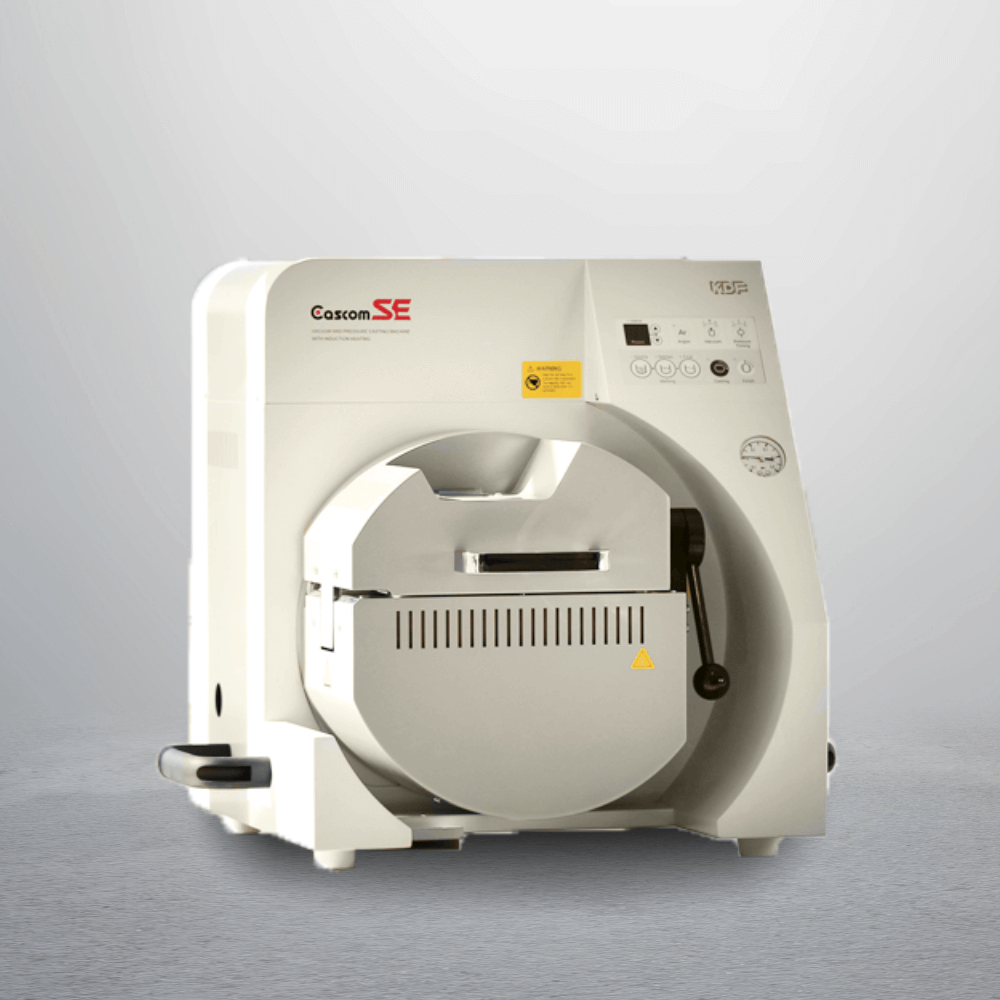

Cascom SE

KDF’s newly developed Cascom SE casting machine features high-frequency induction heating of an alloy and vacuum and pressure casting.

Cascom SE

Sold only in the U.S. and Mexico

In addition, Cascom SE creates extremely smooth surface with argon gas function, implements super quick casting process and is capable of casting various types of alloy such as precious, semi-precious, and non-precious.

It is user-friendly and very simple to operate.

Cascom SE is authentically manufactured in Japan.

PRODUCT INFORMATION

Induction Heating

Cascom SE uses high-frequency induction heating to deliver an exceptionally rapid casting process of about 2 to 3 minutes, optimizing workflow efficiency and improving productivity in the lab.

Vacuum Pressure

Cascom SE does not use a flame during the melting process and applies a vacuum during casting to prevent alloys from absorbing gas, thus minimizing porosity and creating extremely smooth surfaces. A vacuum and pressure casting method is utilized which results in razor-sharp margins and extremely dense casts.

Alloys

Cascom SE is designed to cast all types of alloys (with the exception of titanium) for the fabrication of a variety of restorations, including inlays, crowns, implants, and even partial frameworks.

Cobalt-Chrome Alloy

- One of Cascom SE’s most attractive characteristics is its ability to cleanly cast Co-Cr alloy at high temperatures.

- Co-Cr metal is often used in the fabrication of restorative frameworks. However, the metal is difficult to work with because it requires very high temperatures to melt.

- Cascom SE provides an ideal solution for clean and consistent Co-Cr casting results. The unit allows users to inject Argon Gas inside of the muffle chamber during the melting process, which creates a very clean atmosphere.

- In addition, the Cascom SE’s chamber inverting casting method completely prevents oxidation.[/vision_one_half]

Cooling System

Coolant Machine (Sold separately)

Cascom SE utilizes HPC-20 which is a Chiller for Cascom SE’s cooling system. Like a radiator for a car, the chiller holds coolant and water that circulates into the unit.

Requirements

- The unit requires 220V with 50/60Hz. Max. 3.5kVA

- Requires 100psi to 145psi of pressurized air

- Argon Gas Tank with a Regulator (if you cast a metal that contains Palladium for more than 30%)

220V Outlet

Hose

Φ10mm hoses are coming with the unit. This hose is to connecting between ❶ an air compressor and the unit,

❷ a regulator of an argon tank and the unit.

Specifications

Power Requirement:

AC 220V – 240V 50/60Hz. Max. 3.5kVA

Dimension:

22 (w) x 19 (h) x 19 (d) inches

Weight:

85lbs (38.5kg)

Melting:

Induction Heating

Casting:

Vacuum and Pressure

Pressurized Air:

100psi – 145psi

Output Frequency for Induction Heating:

30 – 50kHz

Max Melting Capacity:

Precious Alloy 120g

Non-Precious Alloy 60g

Heating Performance:

Within 3min When Melting Co-Cr

Casting Ring Size:

Max. Ø90 x 70Hmm

Min. Ø34 x 50Hmm

Cooling Method:

Chiller